Hampshire based Chromatec have introduced fast prototyping and Vapour Phase soldering transforming the way they assemble high technology PCB’s for the Broadcast industry. All of the new equipment has been supplied and installed by Blundell Production Equipment.

Chromatec design and manufacture specialised products for TV broadcasters. Customers include the BBC and Sky amongst others. The work is not high volume but is definitely high technology. Some of their boards are up to 12 layers populated with 900 pin BGA’s on a 1mm pitch along with other smaller BGA’s, QFP’s and QFN’s on 0.8mm pitch. Their designs are constantly changing as the technology develops and as customers want even more functionality

Chromatec’s director Wendy Aitken says that before installing the new equipment all the work was contracted out to CEM’s. Wendy Aitken says “All our designs are done in house and a large proportion of the work is prototypes – we assemble up to up to 40 different prototype PCB’s a year. Putting out one-off boards like this to contract manufacturers is very expensive, up to £600 per PCB. We also had to pay extra for tooling such as stencils, so the cost was really holding us back. And to be honest the CEM’s didn’t really want this kind of work. They wanted higher volumes in regular batches, usually quoting 3 to 4 week lead time. We just don’t work like that. In house we can cut the lead time to a couple of days.”

Wendy continues: “The watershed came when we took on our largest order to date, a large contract to supply multiviewers to a Broadcast Playout facility in Malaysia. These are complex products with several different boards to be delivered on a fixed timescale and budget. The only way to deliver the order and make the desired margin was to invest in our own assembly facility. We had assumed that the cost of our own assembly line would be out of reach but when we approached Blundells’ they showed us how it could be done economically.”

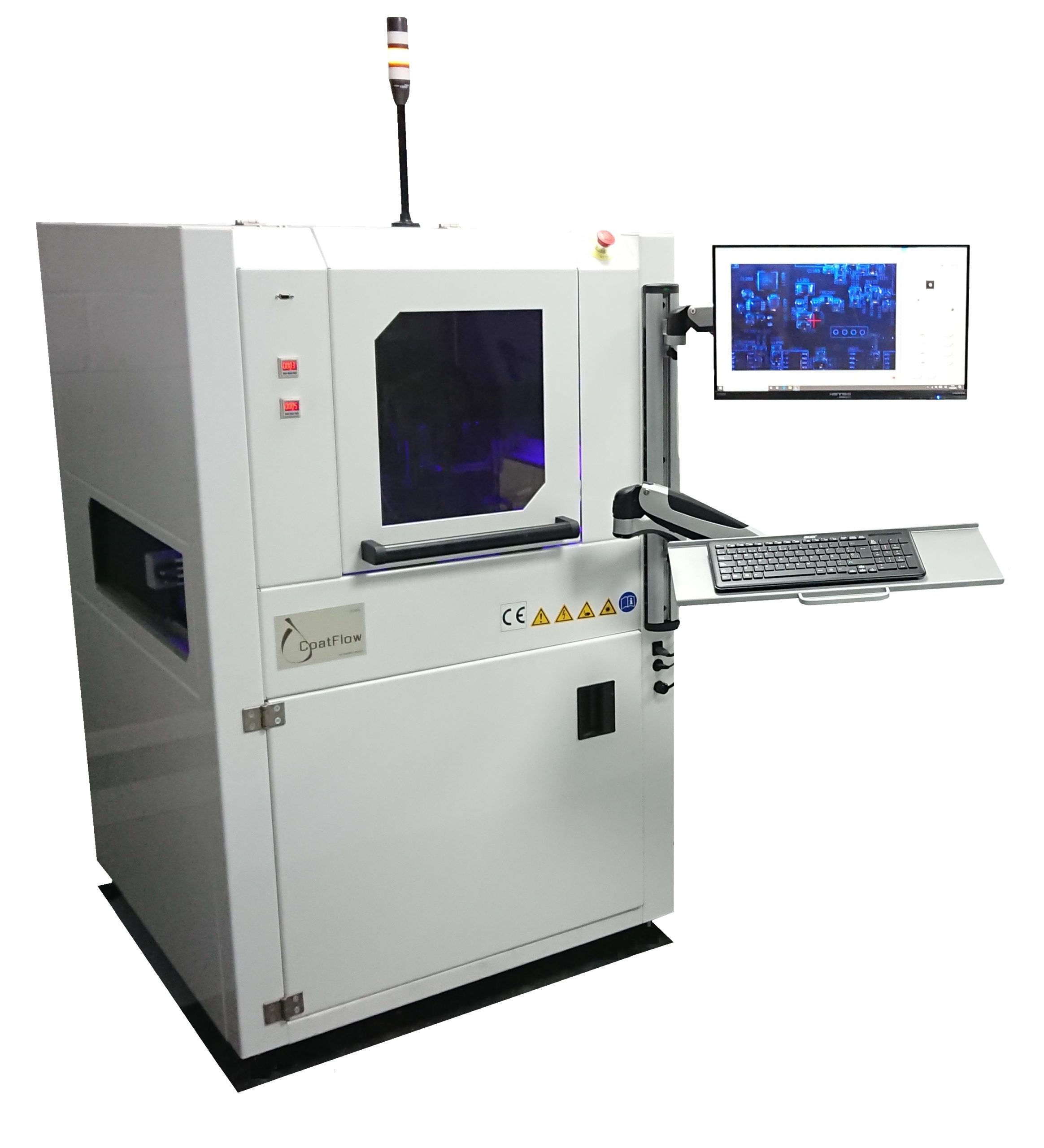

The line that Chromatec purchased from Blundell consisted of a TWS SR2700 automatic bench-top screen printer, a TWS Quadra Evo SMT placement machine and an IBL Vapour Phase reflow soldering system. There was also an investment in an EMT humidity controlled storage cabinet (also from Blundell) to keep kits and part built boards in a controlled atmosphere.

When asked what the benefits have been Wendy says “The best part is that the whole process from engineering and CAD design through to delivery to the customer is in our hands. We have much greater control over the whole process, and we also have a closer relationship with suppliers, scheduling stock in as it’s required. Now we only sub-contract bare PCB manufacture and metalwork fabrication. Using the TWS Quadra SMT placer has allowed us to work with our PCB manufacturer and to specify the way we want the PCB’s to be panellised to best suit the production process. It’s also substantially cheaper to source the PCB’s and stencils ourselves.

Wendy sums up “Everyone at Blundells’ has given us excellent support throughout the installation process and ongoing. It would have been difficult for us to complete our biggest order to date, delivering on time and on budget without this support. We really feel in control now and of course we wish we had done it earlier”

FOR MORE INFORMATION CONTACT PAUL OR NEIL BLUNDELL ON 02476 210270 or email sales@blundell.co.uk