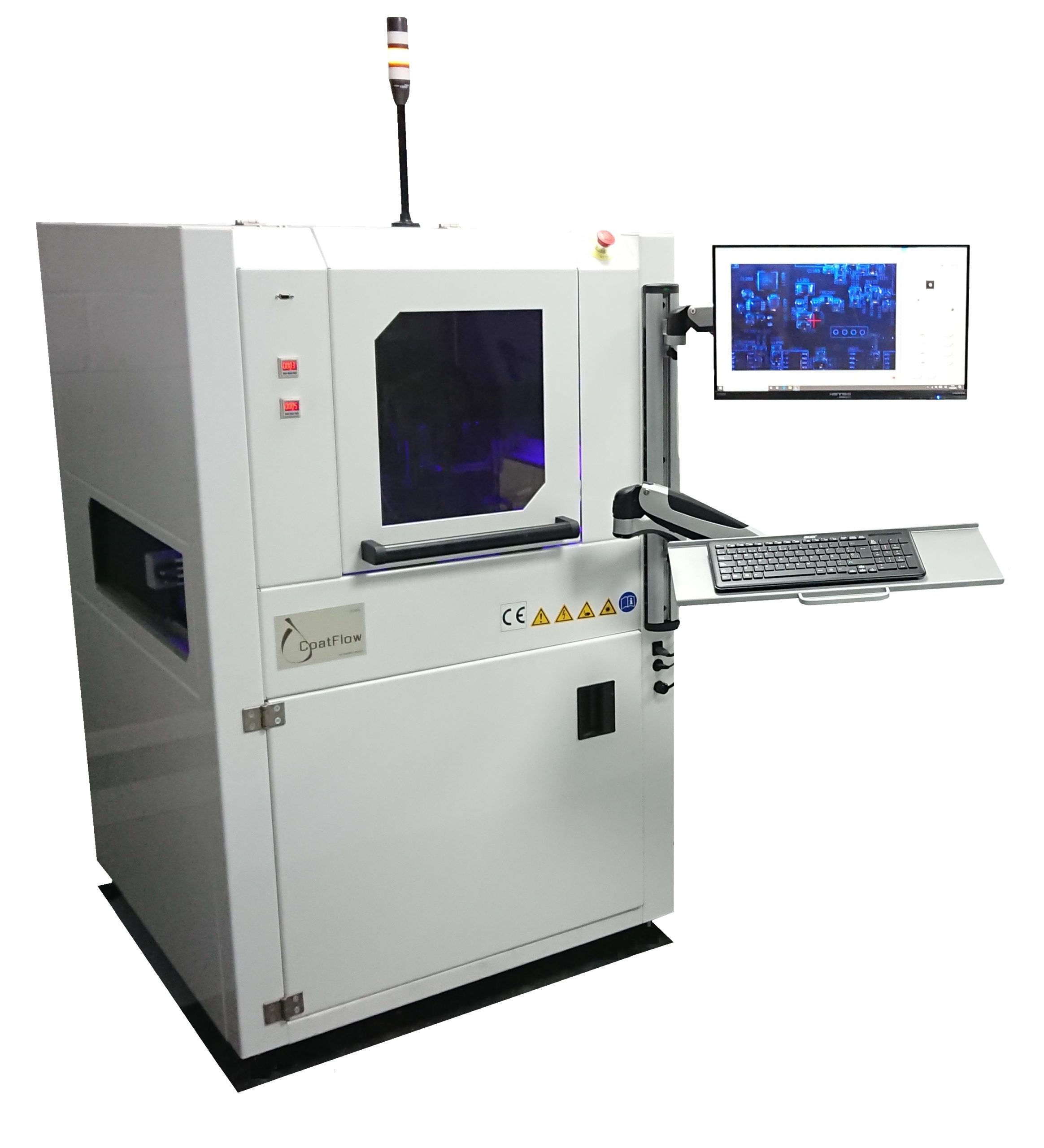

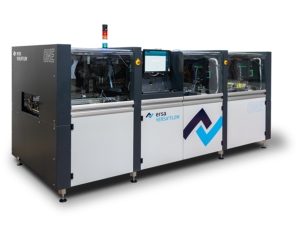

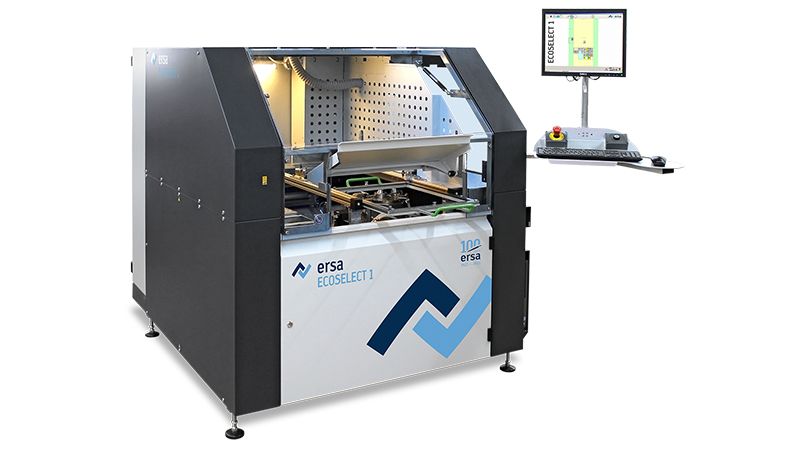

Ecoselect 1 Selective Soldering System

Small Selective Soldering System with outstanding technology.

- Compact batch system with small space requirement

- Same components and software modules from the well-known VERSAFLOW 3 platform

- Highest quality of the products, also in the entry level of selective soldering

Machine enquiry

- OVERVIEW

- DOWNLOADS

- VIDEOS

With the ECOSELECT-1 Ersa is expanding its model range of selective soldering machines introducing a system which fills the entry level small to medium batch production gap. With its small footprint of less than 3 m² this batch machine is a perfect fit into such an environment.

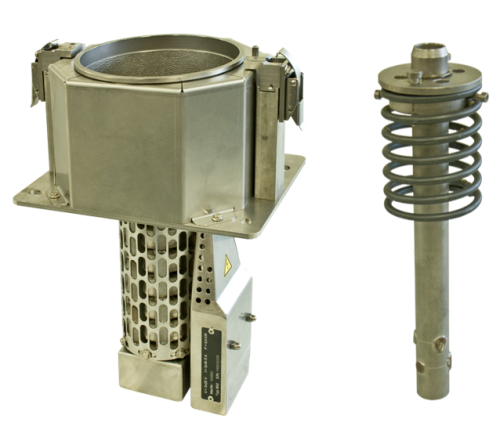

Selective Soldering Technology

The ECOSELECT 1 operates in the same way as the proven Ersa selective soldering technology of the larger VERSAFLOW models, suffering no compromise in regards to quality and accuracy. The universal pallet mount allows processing boards with the size of up to 424 x 508 mm (optionally available 508 x 508 mm). The fluxer performs with the highest positioning accuracy and with the least amount of flux deposition.

Spray Jet Monitoring

Features such as spray jet monitoring for consistent, continuous pressure of the flux supply tank, ensure the presence of the proverbial Ersa process repeatability. Like the VERSAFLOW, the ECOSELECT 1 is equipped with a full area pre-heater cassette. The lower heater is furnished with 8 emitters, which can be switched in groups so that the power consumed can be adapted to the heat demand and the size of the board. The upper convection heater of the ECOSELECT 1 is optimally matched with the lower pre-heater, ensuring an effective and reproducible soak for even the most demanding board assemblies.

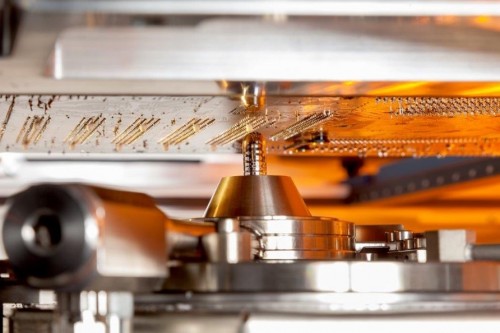

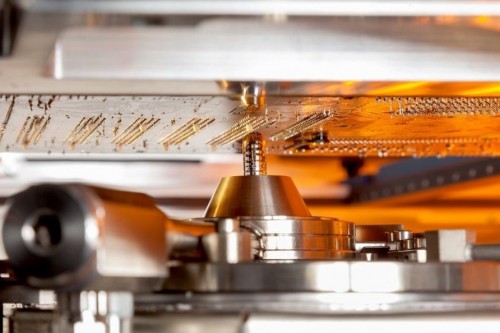

Innovative Dual Pot System

As are the large VERSAFLOW systems, the solder module of the ECOSELECT 1 comes with electromagnetic pump, so that the bath is extremely low on maintenance. The pump ensures a very constant flow rate of solder and delivers therefore an exact and finely adjustable wave height. Dynamic process parameters such as solder level in the bath, solder wave height and solder temperature are continuously monitored and documented. With the innovative “peel off” feature, defects such as bridging when soldering at the 0° level are definitely no issue. The dual pot system allows for two different alloys to be used in the process or two different nozzle sizes. Downtime of the system due to pot/nozzle change are thereby reduced to a minimum. The solder pot can now also operate with the very latest mini-wave, mini-dip wave and area-soldering nozzles giving the option to operated like a small wave solder machine.

The ECOSELECT is operated via PC controls with ERSAsoft. The process writer, which continuously records the actual values of all elements relevant to the soldering process, and the solder protocol, (process data with all info required for traceability as per ZVEI standard) are part of the standard system specification.

Standard alarm management allows all notifications to be stored showing a time stamp and the user identification. All data is available in the XML format, and can therefore be easily worked on.

With the help of the CAD assistant, DFX data of printed circuit boards can be used to create solder programs. As a rapid alternative, a scanned-in picture of the board can also be employed, all movements of the fluxer and the solder bath to be executing are graphically entered on the picture of the board this data is then downloaded to ERSAsoft. The program thus created can immediately be used on the ECOSELECT 1.