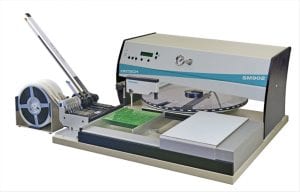

TWS-850 Batch Reflow & Baking Oven

Is a powerful and compact convection oven with one heating zone but two heating phases, capable of replicating a three or four zone tunnel oven. Ideal to perform soldering operation for small to prototype size SMT manufacturing, to cure adhesive and pastes and to remove humidity from fine pitch parts prior to reflow using Hot Bake function.

×

Machine enquiry

- OVERVIEW

Features

- Capable of reflowing boards up to 330 mm length and 240 mm wide.

- Heating of the board is by forced air convection, a well-proven system, giving the best compromise among quality, productivity, consumption and dimensions

- Gentle forced convection ensures uniform heating without the danger of disruption to component placement

- Easy to use and with good performance

- Powerful enough to produce perfect results in in short cycle times even on a large pcb

- Bench-top model is ideal for small production, prototyping and laboratory work

- The electronic control system is designed to minimise power consumption

- Any number of thermal profile can be developed

- The actual temperature of the heater is monitored by computer and a built-in K-type thermocouple

- The oven’s main parameters are constantly monitored by the Touch screen LCD display

- Display show:

- Temperature set-point for each heating phase

- Actual temperature for each heating phase

Note:- There is no option to save profiles, therefore a time – temperature chart for different profiles would have to be maintained.